Hunt's Proven Carbon Trail H_Core wheels boast impressive strength-to-weight numbers, while keeping the price tag well below big name rivals.

Hunt’s latest carbon wheels are almost as strong and lightweight as Gucci brands’ like Enve and DT Swiss, but cost less than half as much in some cases. That’s the claim from Hunt anyway, which has spent over three years developing its new Proven wheelset, which now includes something called “pultruded, carbon-dense inserts”.

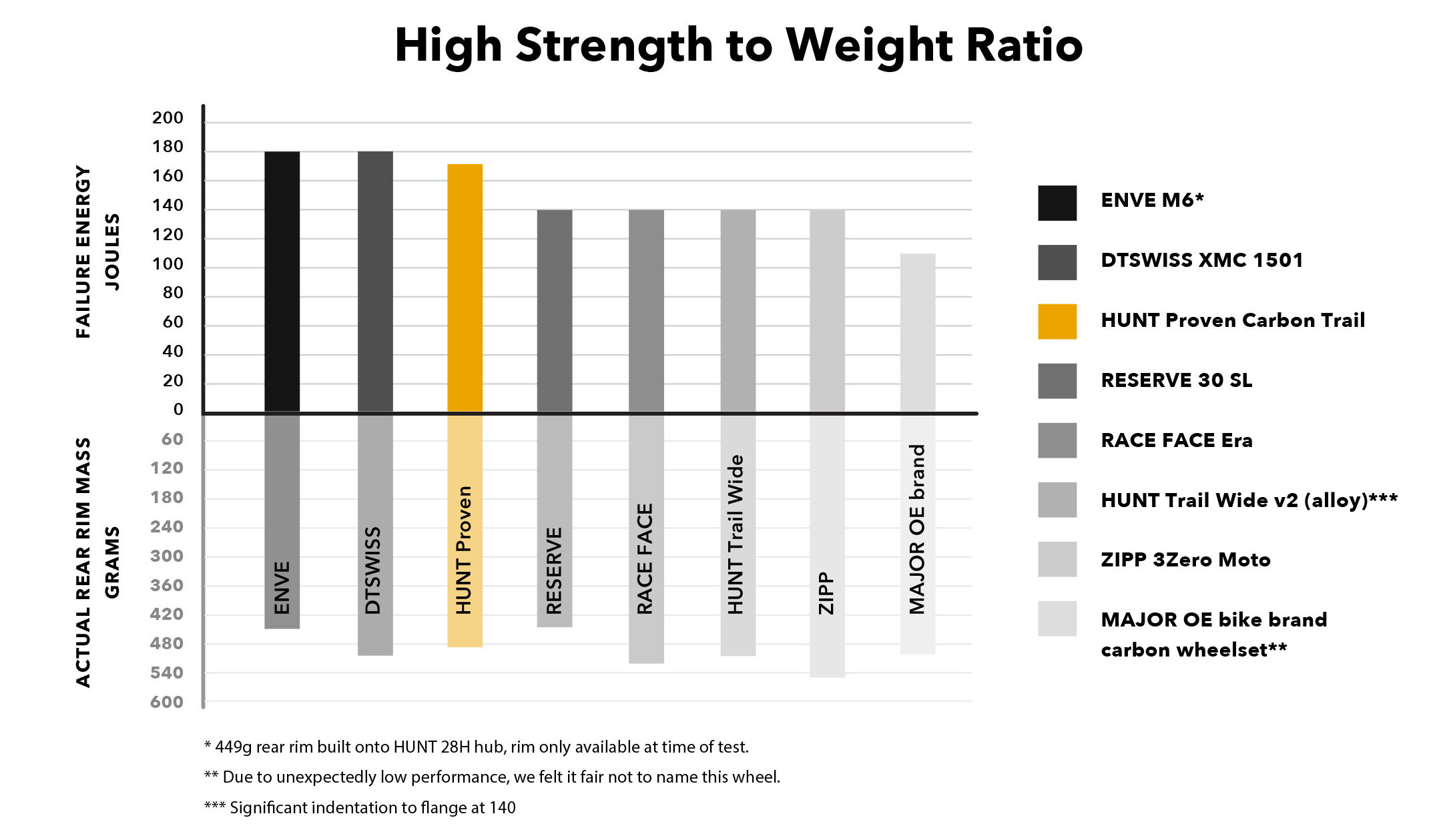

According to Hunt’s testing, its Proven Carbon Trail H_Core rear wheel can withstand 170 joules of energy before cracking. That bests the likes of Santa Cruz Reserve 30 SL, Race Face ERA and Zipp’s 3Zero Moto rear hoops in Hunt’s in-house trials. Only Enve’s M6 rim and the DT Swiss XMC 1501 wheel took more of a beating in the lab before failing. But you’ll pay a hefty premium for that extra strength – the Enve M6 are £2,500, while the Hunt wheelset costs £1,199.

Impressive claims then, but there’s no substitute for real world testing against the best mountain bike wheels on the market, where the right balance of compliance and stiffness make or break a wheel. So we’ll get a full review on the new Provens later in the year. The tests are carried out on ‘multiple’ samples of each rim, so while there will be a tolerance across individual examples, Hunt’s tests give a reasonable insight into relative strength.

The new Proven Carbon Trail H_Core wheelset weighs a claimed 1,732g – light, but not as svelte as the 1,565g claimed weight of DT Swiss’s XMC 1501

Proven Carbon Trail H_Core need to know

- New carbon wheelset claims high strength for low weight and price

- Uses “pultruded, carbon-dense” inlaid carbon bead strips to ensure no voids or wheel failures

- Tuned wheels, with front wheel more compliant and the rear stiffer and stronger

- 10k carbon weave material for more compliance to prevent “micro-cracks”

- Designed for bikes up to 160mm in fork travel

- Hunt-designed hub gets 2º hub engagement, 90-tooth ratchet with 6 double-tooth pawls.

- Wheelset weighs 1,732g (29er pair) or 1,719g in mullet

- Lifetime crash replacement

- Price: £1,199 | $1,499 | €1,449

Hunt told me its data is really about showing it can cut it alongside the best wheel builders in the business

The big change over the older Hunt Proven wheels is the edition of the H_Core. It sounds like an obscure computer programming language, but really it’s just a strip of carbon running the circumference of the bead on each side of the rim. Simple, but hugely important when it comes to reducing wheel failures and adding strength without making the wheel heavier or too rigid, Hunt says.

The H Core is there to prevent any voids or holes in the carbon as it’s formed, something that can lead to weak points and failures

Here’s the really geeky bit then, Hunt adds these carbon inserts before the wheel has been laid up, they’re pre-cured and pultruded and then the carbon rim is built around this framework. Pultruded refers to a process where the resin-coated fibres are pulled through a heated die (hence the combination of ‘pulled’ and ‘extrusion’) to form a specific shape, and continuous cross-section, then cut to the desired length.

Why bother? Hunt says this pretty much guarantees there are no voids or holes in the carbon, something that’s impossible to 100% eliminate, or even check, on any carbon rim from any manufacturer. Hunt told me the first time you’re usually aware of a flaw in carbon construction is when your wheel cracks, usually at the crucial stress point between the rim bed and sidewall. More conventionally, Hunt has also made its rear wheel with a 4mm rim-bead-width to reduce pinch flats, the logic being it’s less likely to slice through your tyre’s sidewall than a skinny bead.

Why bother? Hunt says this pretty much guarantees there are no voids or holes in the carbon, something that’s impossible to 100% eliminate, or even check, on any carbon rim from any manufacturer. Hunt told me the first time you’re usually aware of a flaw in carbon construction is when your wheel cracks, usually at the crucial stress point between the rim bed and sidewall. More conventionally, Hunt has also made its rear wheel with a 4mm rim-bead-width to reduce pinch flats, the logic being it’s less likely to slice through your tyre’s sidewall than a skinny bead.

I loved the Crankbrothers Synthesis for its ride feel, never mind strength and weight, and Hunt has followed a similar ride-tuned concept.

Tuned wheels

Hunt isn’t the only brand to tune its wheels front and back, offering different amounts of flex at each end of your bike, the Crankbrothers Synthesis did it years back. But Hunt goes about it by altering the carbon lay-up, the rim width, and the spoke gauge, in a triple-pronged attack on riding characteristics.

Hunt says there’s a lighter carbon lay-up on the front, weighing some 20g less than the rear (based on 29in rims). The rear rim is also 1mm narrower, with a 30mm internal width to reduce rolling resistance, while the front spokes are just 1.6mm in the centre of their span, to the rear’s 1.7mm.

All the data in the world is nothing to how a wheelset feels when you’re riding it.

All this, it’s claimed, leads to the holy grail of carbon wheels; better compliance and traction at the front, alongside greater strength, stability, rolling resistance and stiffness on the rear.

Look out for a full test on these wheels soon, once we’ve had a chance to put them through their paces.